Tailored Revisions

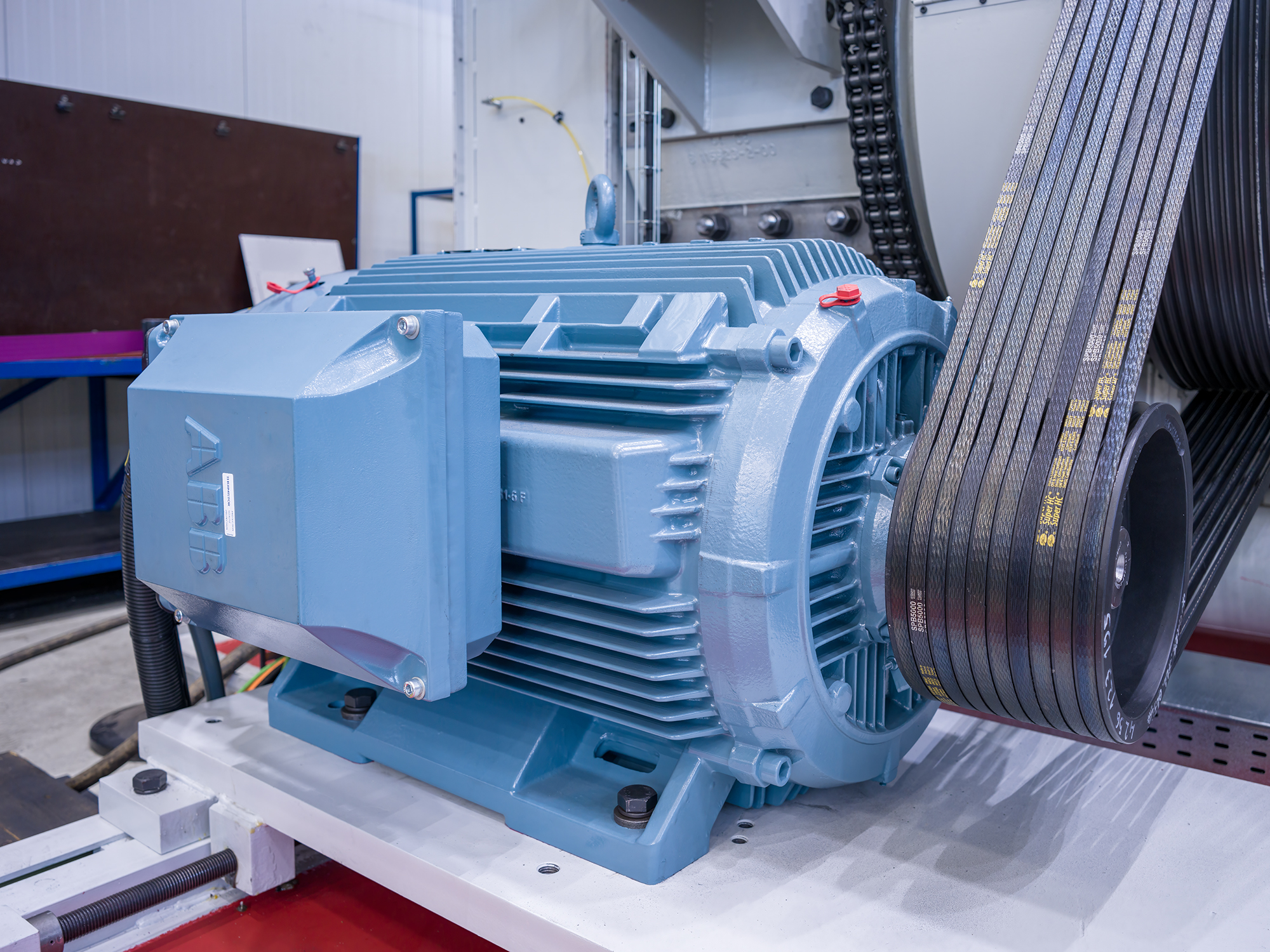

Revisions (also known as retrofitting or refurbishing) go beyond standard inspections. They include adjustments and improvements based on customer-specific needs and the latest technology. As machines age, repair costs rise making revision a smart, cost-effective alternative.

We offer tailored solutions and a dynamic approach that adapts to your needs. Together with our customers, we adapt machines to match evolving production requirements, incorporating technological advancements to maximize efficiency and performance.

By performing software upgrades or installing additional modules, we add functionality to increase automation levels and make operation easier.

The Power of Upgrading

Many Nedschroef machines retain a structurally stable and high-quality base, even after decades of service. Key benefits of upgrading an existing machine include:

- Upgraded control, safety & automation: Modern systems integrated to meet current CE and safety standards, improving operator ease and reducing errors.

- Improved productivity & flexibility: Faster changeovers, restored mechanical speed, and higher output ensure efficient operations with fewer delays.

- Reduced downtime & lower investment: Shorter installation time and fewer disruptions compared to buying new machines, significantly more cost-efficient.

- Full compliance & future-proofing: Adheres to all industry standards while boosting reliability, stability, and long-term operational value.

- Smart refurbishment, not replacement: Enhanced performance through mechanical restoration and tech upgrades at a fraction of the cost of a new machine.

Our 7-Step Process

Restored with Precision Ready to Perform

- Investigation and initial validation of the machine's condition

- Disassembly of structural components and inspection and evaluation of all components

- Adjustment, repair, or replacement of functional components

- Component machining and grinding, cleaning and painting

- Replacement and upgrading of electrical, pneumatic, and hydraulic parts

- Assembly and adjustment of structural components

- Installation and commissioning, calibration, functional tests, and customer acceptance

Compliance with all safety and CE standards is ensured throughout the entire process.

Smart Standardization & Modernization

Upgrades That Make a Difference

We replace outdated systems like Nedtronic I or II with our latest NedControl platform; This includes remote access through EWON modem, automated adjustments using Lenze servo motors, and retrofittable enhancements such as NC servo feed units. From PLCs and interfaces to operator safety improvements, every rebuild is engineered to improve productivity, achieve tighter tolerances, and surpass the original machine's Overall Equipment Effectiveness (OEE).